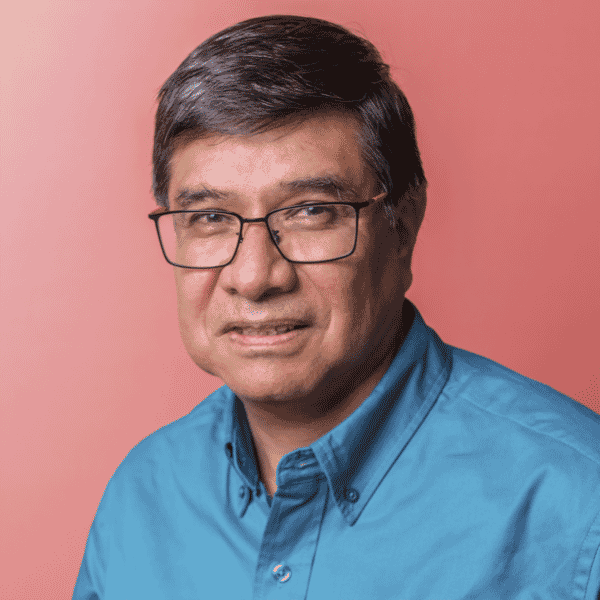

About Levi Guzman

Levi Guzman, Molycop's Peru-based Technical Director, specialises in Geometallurgy, Mining Innovation and Mineral Processing, optimising operations through innovative strategies. Levi’s leadership in applying cutting-edge technology enhances efficiency and sustainability, making him pivotal to Molycop's commitment to innovation in mineral processing.