Dr. Paul Shelley, Vice-Presidente de Inovação da Molycop, destaca como a pegada de energia do moinho SAG está em foco e está levando a uma reformulação da eficiência do circuito, do equipamento e do design.

Fatos Importantes

- O setor de mineração depende dos fornecedores para sua inovação, com a tecnologia incorporada em máquinas, serviços e outros insumos que impulsionam a inovação.

- A necessidade de eficiência energética e a adoção da transformação digital estão fazendo avançar o design e o planejamento dos equipamentos.

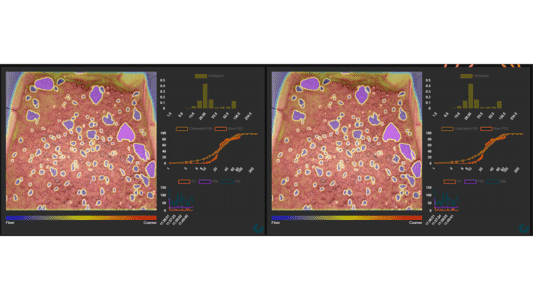

- As plataformas digitais que usam técnicas estatísticas avançadas, IA e machine learning estão mudando a forma como o setor pensa sobre moagem.

As mudanças mais significativas no setor de mineração têm origem nas principais empresas de mineração do mundo, que se comprometeram formalmente a atingir emissões líquidas zero de carbono de escopo 3 até pelo menos 2050. A pegada de energia do moinho semi-autógeno (SAG) está em foco e está levando a repensar a eficiência, o equipamento e o design do circuito. As iniciativas resultantes levarão a grandes mudanças na moagem SAG no futuro imediato.

A transformação digital

A Inovação e a Transformação Digital (TD) surgiram como agentes essenciais para resolver os desafios do setor.A tecnologia incorporada em máquinas, serviços e outros insumos permite que a inovação ocorra no setor. A tendência atual é o monitoramento baseado em sensores da cadeia de processos, incluindo os processos de moagem. As propostas de valor que mostram como as plataformas digitais usam técnicas estatísticas avançadas, inteligência artificial e algoritmos de machine learning para prever os estados operacionais do moinho SAG em tempo real estão amadurecendo. Esses sistemas têm uma profunda influência nas operações atuais e estão mudando a forma como as mineradoras pensam sobre moagem no curto prazo.

Desenvolvimento de produtos

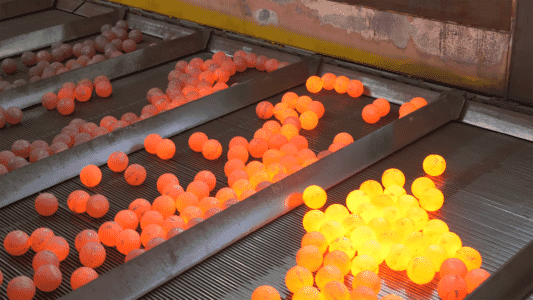

A busca pela eficiência energética e a adoção da transformação digital estão fazendo avançar o design e o pensamento dos equipamentos. O desenvolvimento de materiais mais duráveis para revestimentos de moinho e mídia de moagem é uma tendência significativa. Esses tipos de desenvolvimento de produtos mudarão significativamente a operação do moinho SAG, se não o substituírem por completo.

Catalisadores de mudanças no futuro do setor

O futuro imediato do moinho SAG é de mudanças. Muito provavelmente as mudanças serão:

- Impulsionadas pela transformação digital e pela influência da operação do moinho SAG e dos paradigmas operacionais. Isso parece ser particularmente verdade no monitoramento do moinho, na análise de dados, no controle de processos e em máquinas virtuais.

- Modificações na frota implantada existente em vez de substituição em massa.

- Influenciadas em grande parte pela validação de equipamentos emergentes como CAHM, HPGR, classificação e fragmentação de minério.

- Personalização. Dada a variabilidade das propriedades do minério em diferentes locais de mineração, há uma necessidade crescente de moinhos SAG que possam ser personalizados e flexíveis nas operações.

- Inúmeras. É de se esperar que as iniciativas dos fornecedores gerem mudanças incrementais e interrupções.

- Com base na crescente visibilidade e homogeneidade do minério de alimentação. A variabilidade é o vilão.