Les services d'optimisation des procédés de Molycop améliorent les opérations minières à l'échelle mondiale.

Faits clés

- Le prix de l'or et du cuivre a considérablement augmenté – les mineurs devraient en profiter pour maximiser la production dès maintenant.

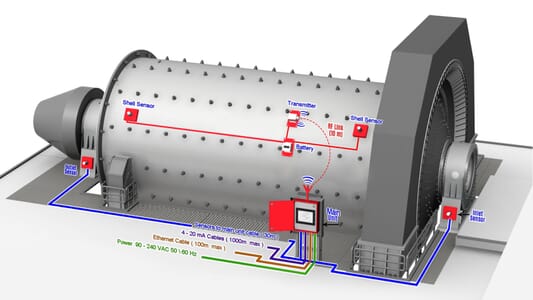

- La technologie et les services d'optimisation des procédés de Molycop permettent aux entreprises d'améliorer le débit, la récupération et l'efficacité de leurs opérations.

- Grâce à des technologies telles que MillROC et MillSlicer, la société minière Resolute a pu économiser jusqu'à 4 millions de dollars US par an uniquement sur les coûts de rechargement des broyeurs et les temps d'arrêt.

Début avril, les prix de l'or ont atteint 2400 $US l'once pour la première fois, et le cuivre a atteint un niveau record de plus de 10 889 $US la tonne. Le marché des métaux est en effervescence, ce qui est une bonne nouvelle pour Molycop, dont la clientèle est principalement composée de mineurs d'or et de cuivre.

"En ce moment, les choses se passent bien dans l'industrie de l'or d'un point de vue prix", a déclaré Pieter Strobos, Vice-président commercial d'Australasie chez Molycop, à Australian Mining. "Les mineurs doivent profiter de la situation en maximisant la production."

Prenons l'exemple de Resolute Mining, qui exploite la mine d'or Mako au Sénégal. En combinant les technologies et l'expertise de Molycop et Orway IQ, le temps d'arrêt prévu a été réduit de 25%, ce qui a bénéficié de manière significative aux résultats financiers de Resolute.

"Molycop possède la technologie, les compétences et l'expertise pour aider les entreprises minières à augmenter leur production en augmentant le débit et la récupération tout en réduisant le gaspillage d'énergie et de réactifs", a ajouté Strobos.

En tant que l'un des fournisseurs de produits et de technologies minières les plus connus et les plus fiables au monde, avec une réputation particulière dans les industries de l'extraction du cuivre et de l'or, Molycop aide les entreprises à améliorer leur débit, leur récupération et leur efficacité grâce à sa technologie et à ses services d'optimisation des procédés.

"Nous faisons cela grâce à des instruments avancés, un contrôle de processus avancé, la modélisation des processus et la technologie des jumeaux numériques", a déclaré Strobos.