Une session de formation organisée avec Nexa Resources a offert à Molycop l'occasion de travailler avec un client précieux pour fournir expertise, innovation et solutions afin de stimuler leur progression.

Faits clés

- La session de formation a été conçue pour améliorer l'efficacité opérationnelle de Nexa et fournir des informations pratiques sur l'optimisation des circuits de broyage et le traitement des minéraux.

- La session a fourni des informations sur l'analyse du flux des médias de broyage, le dimensionnement des médias de broyage, la simulation et l'optimisation de la flottation, l'échantillonnage des minerais et l'analyse de l'abrasion, ainsi que sur les outils Molycop et les simulations DEM.

- Le programme de formation a été adapté aux besoins de Nexa afin qu'ils puissent apprendre à optimiser leurs processus.

Ce programme de formation collaboratif, dirigé par Rodrigo Muranda, Responsable mondial de la modélisation du traitement des minéraux, et soutenu par Renata Martins, Responsable de compte senior, a été conçu pour améliorer l'efficacité opérationnelle de Nexa et fournir des informations pratiques sur l'optimisation des circuits de broyage et le traitement des minéraux. Le programme de formation s'inscrit dans le cadre de la relation de longue date entre Molycop et Nexa.

Une plongée approfondie dans l'optimisation des circuits de broyage

Une plongée approfondie dans l'optimisation des circuits de broyage

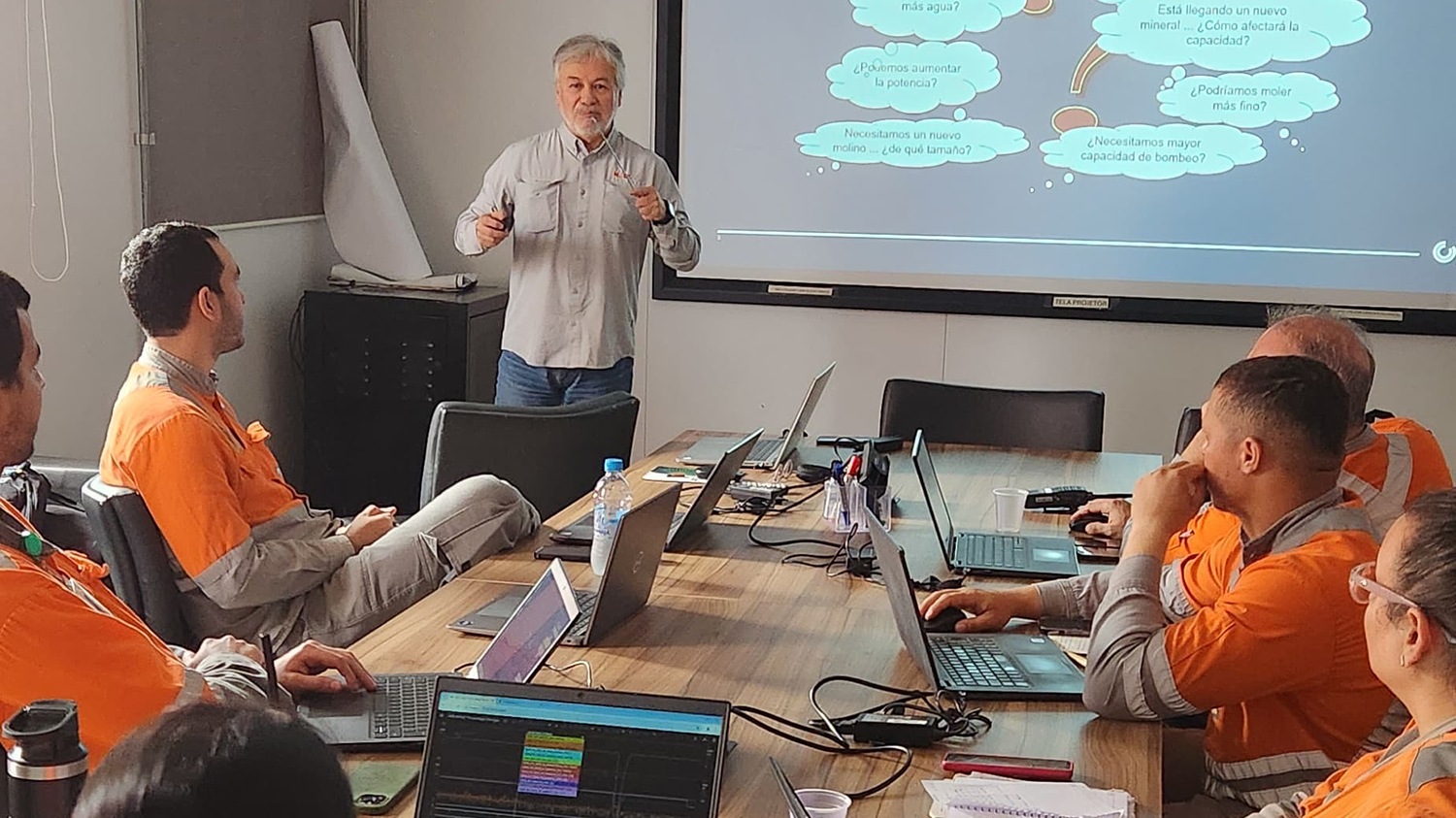

Le programme de formation a couvert un large éventail de sujets essentiels pour l'optimisation des circuits de broyage, adaptés aux besoins des opérations de Nexa. Les participants ont reçu des informations détaillées sur les points suivants :

- Analyse du flux des circuits de broyage : L’équipe a réalisé un examen approfondi des circuits de broyage de Nexa, identifiant les principales zones d'optimisation et d'amélioration de l'efficacité.

- Dimensionnement des médias de broyage : Un dimensionnement adéquat des médias est essentiel pour une performance optimale du broyeur. Notre session s'est concentrée sur le choix des bons médias afin de maximiser le débit et l'efficacité énergétique.

- Simulation et optimisation de la flottation : Nous avons dispensé une formation avancée sur les techniques de simulation de la flottation pour optimiser les taux de récupération et améliorer la performance globale de l’usine.

- Échantillonnage des minerais et analyse de l'abrasion : Un échantillonnage précis des minerais et des tests d’abrasion sont cruciaux pour comprendre le comportement des matériaux. Nous avons fourni à l’équipe de Nexa les meilleures pratiques pour réaliser ces évaluations.

- Outils Molycop et simulations DEM pour le désengorgement des circuits de broyage : La session s'est conclue par une exploration des outils logiciels de pointe de Molycop et des simulations de la méthode des éléments discrets (DEM), montrant comment ces technologies peuvent aider à désengorger les circuits de broyage et améliorer la productivité.

Construire des partenariats à long terme

Construire des partenariats à long terme

La formation tenue à Aripuanã n’a pas seulement consisté à partager des connaissances techniques, mais aussi à renforcer la philosophie fondamentale de Molycop. Nous ne nous voyons pas simplement comme un fournisseur de médias de broyage ou de services – nous nous considérons comme un véritable partenaire dans le succès de nos clients. Notre approche repose sur la collaboration, des objectifs communs et un engagement profond à aider nos clients à réussir. Nous travaillons main dans la main avec nos partenaires pour identifier des opportunités d'amélioration, mettre en œuvre des solutions innovantes et optimiser en permanence leurs opérations.À mesure que Nexa Resources continue d'étendre et d'optimiser ses opérations, nous serons présents à chaque étape du processus, en fournissant l'expertise, les outils et les technologies nécessaires pour atteindre leurs objectifs.

Regarder vers l'avenir : Un engagement continu envers le succès

Regarder vers l'avenir : Un engagement continu envers le succès