Molycop joined Codelco in a workshop aimed at leveraging advanced technologies to drive efficiency across grinding processes.

Key Facts

- Members of Molycop’s Chilean team participated in the inaugural ‘Andina Process’ workshop.

- Participants shared strategies for optimising and controlling the internal load in both SAG and ball milling.

- The workshop offered an opportunity for Molycop and Codelco to collaborate on shared objectives.

Members of Molycop’s Chilean team were invited to participate in the inaugural ‘Andina Process’ workshop hosted by Codelco’s Andina Division. This event gathered industry experts, technical teams and partners to exchange valuable knowledge on copper concentrator plant operations and maintenance, emphasising optimising grinding processes.

Driving efficiency in grinding

Driving efficiency in grinding

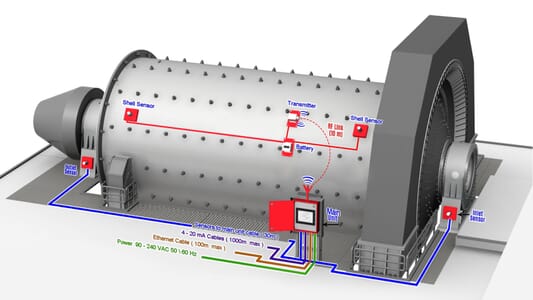

In Molycop’s presentation, the team shared strategies for optimising and controlling the internal load in both SAG and ball milling, underscoring Molycop’s commitment to leveraging advanced technologies to drive efficiency across all grinding phases. The workshop provided Molycop with a platform to align its technical expertise with Codelco Andina’s objectives and foster collaboration to support operational excellence.

Thanks from Molycop

Thanks from Molycop

Molycop extends its thanks to Codelco’s Andina Division for the opportunity to participate. Molycop is proud to support Codelco’s mission to maximise efficiency at every stage and looks forward to continuing its partnership to add value to their operations.

Molycop – Progress Together

Driving efficiency in grinding

Driving efficiency in grinding  Thanks from Molycop

Thanks from Molycop