Observations of operations management of Minerals Processing Mills – Dr Paul Shelley

Key Facts

- The objective of operations management is to manage the production of a maximum volume of units in the shortest time, at the agreed quality, for the lowest cost.

- Operation of a mineral processing circuit is beset by variabilities in operating conditions.

- AI, increasingly advanced sensors and momentum towards reducing waste in the operating system will combine to reduce variability in the mineral processing circuit.

Operating Systems / Process Control

Operating Systems / Process Control

In his latest article for Metals & Mining Review magazine, Dr Paul Shelley, VP of Innovation for Molycop, explains that the objective of operations management is to manage the production of a maximum volume of units in the shortest time, at the agreed quality, for the lowest cost. The deliverables must include safety maximisation and environmental impact minimalisation, requiring a rigorous, mechanistic and explicit operating system.Two systems that have been widely adopted, deployed and learned throughout the operating world are LEAN and Six Sigma. One can think of LEAN thinking as a ‘war on waste’ within the operating system. An operating system based on Six Sigma teaches one about reducing variability and improving process capability.

It may seem that both operating strategies are ‘competing’ philosophies, Dr Shelley explains, but they have a tremendous amount in common. Both focus on a culture of continuous improvement, root cause analysis, elimination of inefficiencies and a lifetime of assiduous commitment to the cause.

At the same time that operating philosophies were developing, researchers and practitioners in the process control world were exploring the interaction of fuzzy set theory and expert systems in a construct called AI. In the three to four decades since, there have been step changes in Expert Control System capability. Combining operating philosophies and technology in operations has seen profound changes in the manufacturing industry worldwide.

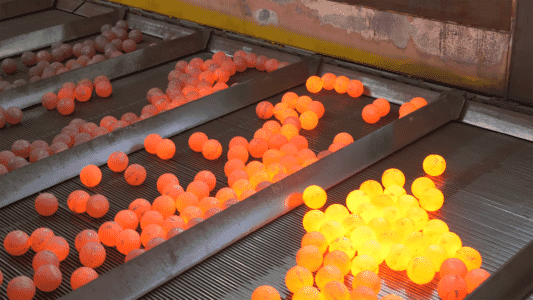

Dr Shelley explains that manufacturing systems are explicit, mechanistic and controlled in real-time. However, some industries find it difficult to maintain adherence to the fundamental principles of an expert control system. This is especially the case in mineral processing circuits, which are large, complex, uncertain and where there can be severe changes in operating conditions.

Summary

Variability is the villain, according to Dr Shelley.He explains that using Moore’s Law of computing power, it is inevitable that AI will close the variability challenge gap in process control of tumbling mills. Supporting the computing power will be technologically advanced sensors that are robust, reliable and repeatable in their data streams.

At the same time, philosophies like LEAN will result in a demand for explicitisation and mechanistic processes, including a war on waste, that erode the variability of the process.

According to Dr Shelley, what's needed is to measure, measure, measure – consistently, assiduously and without variability.

Click here to read the full article.