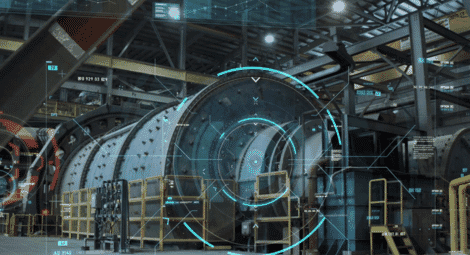

Révolution technologique utilisant de vieux pneus de voiture pour fabriquer de l’acier, mettant fin

"Cette technologie d'injection de polymère nous permet de remplacer probablement environ la moitié de cette quantité par du caoutchouc émietté", a déclaré M. Parker au Daily Mail Australia.

En savoir plus

.png?w=600)

.png?h=256)