Molycop Reflects on a Remarkable Experience at MetPlant Conference 2023

Adelaide played host to the MetPlant Conference 2023, and what a phenomenal experience it was for the Molycop team.

Read More

Molycop is a strong advocate for the use of Polymer Injection Technology (PIT), which uses recycled polymers (such as tyre rubber) as an alternative carbon injectant in the EAF steelmaking process. Using PIT diverts tyres from landfill and reduces electricity consumption and Scope One carbon emissions.

Make An Enquiry

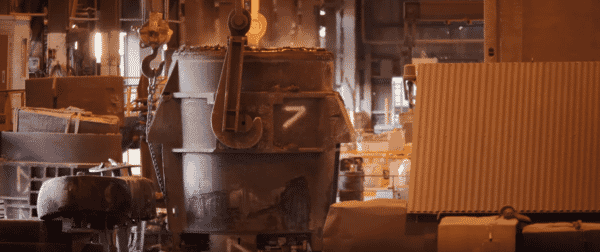

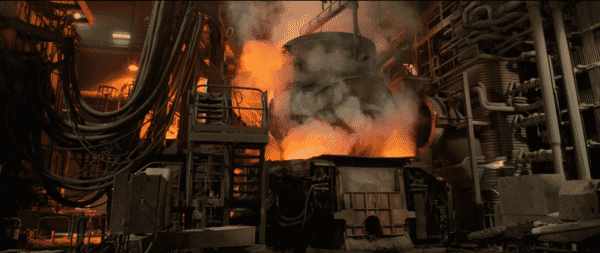

Polymer Injection Technology (PIT) involves partially substituting injectant coke used in Electric Arc Furnace (EAF) steelmaking with polymer materials such as rubber crumb to produce steel.

Molycop is the licensee and global commercial partner with the University of New South Wales (UNSW) for PIT.

Polymer Injection Technology provides EAF steelmakers with the potential to reduce costs by:

EAF steelmakers also have the opportunity to reduce their carbon emissions through lower electrical energy consumption.

In conventional EAF steelmaking the injection of coke or anthracite (coal-based products) produces a foamy slag, which acts as a blanket over the molten steel during the steelmaking process. Polymer Injection Technology provides benefits to EAF steelmakers by improving the foaming properties of the slag, using a blend of polymer and coke/anthracite.

The addition of the polymer to the injectant mix improves the volume and foaminess of the slag. The improved slag foaming results in:

Among the advantages of this are reduced power on time, improved active power, reduced electrode wear and reduced electrical energy consumption. Improved slag foaming also results in a reduction in the amount of carbon injectant consumed per heat.

The addition of polymer to the coke injection also improves the reduction of the FeO in the slag due to the CH4 and H2 generated by the hydrogen, resulting in an increase in yield and significant scrap savings.

There are numerous environmental benefits associated with using Polymer Injection Technology. Among these are:

Molycop holds the exclusive global license with UNSW’s commercialisation arm, NewSouth Innovations, which grants Molycop world-wide rights to sub-license the technology. Molycop has entered into discussions with global steelmakers regarding implementation of PIT within their operations.

With global steel production at 1.9 billion tonnes in 2022 – a quarter of that manufactured in EAFs – PIT has the potential to play an important role in greening the industry. The average EAF steel mill has the potential to consume approximately 200,000 passenger tyres annually.

If you are interested in the deployment of PIT, contact [email protected] for more information.

Founded in 2008 by ARC Laureate Fellow, Scientia Professor Veena Sahajwalla, the Centre for Sustainable Materials Research and Technology (SMaRT) at UNSW works with industry, national and international research partners, and governments across Australia, to develop innovative environmental solutions for the world’s biggest waste challenges.

Molycop’s partnership with UNSW and the SMaRT Centre was born through a shared belief in the importance of innovation and forged through the ongoing exchange of knowledge and resources. From groundbreaking innovations such as PIT to our most recent work in the circular economy space, we look forward to seeing the fruits of our endeavours over the coming years.

I see the future having a ‘materials loop’ where we think of materials as basic elements. In this world, all products will be recycled so that they lose their memory and are given a new life, without compromise. PIT has the potential to play an important role in the repurposing of end-of-life materials.

— Scientia Professor Veena Sahajwalla

Take your operations to the next level by exploring these additional products and services.