Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services to deliver sustainable increased throughput of 27% in 8 months.

- Molycop has successfully implemented a range of optimisation projects at The Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services.

- Optimisation strategy resulted in a sustainable increase in throughput of 27% in 8 months.

- Approximate monthly net cash flow benefit of A$6.3 million (per month).

- Tens of millions of dollars of increased revenue a year at reduced operating costs.

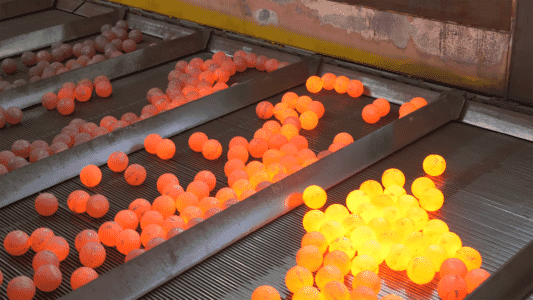

- Optimisation of ball charge and steel-to-rock ratio has resulted in more efficient milling and increased throughput.

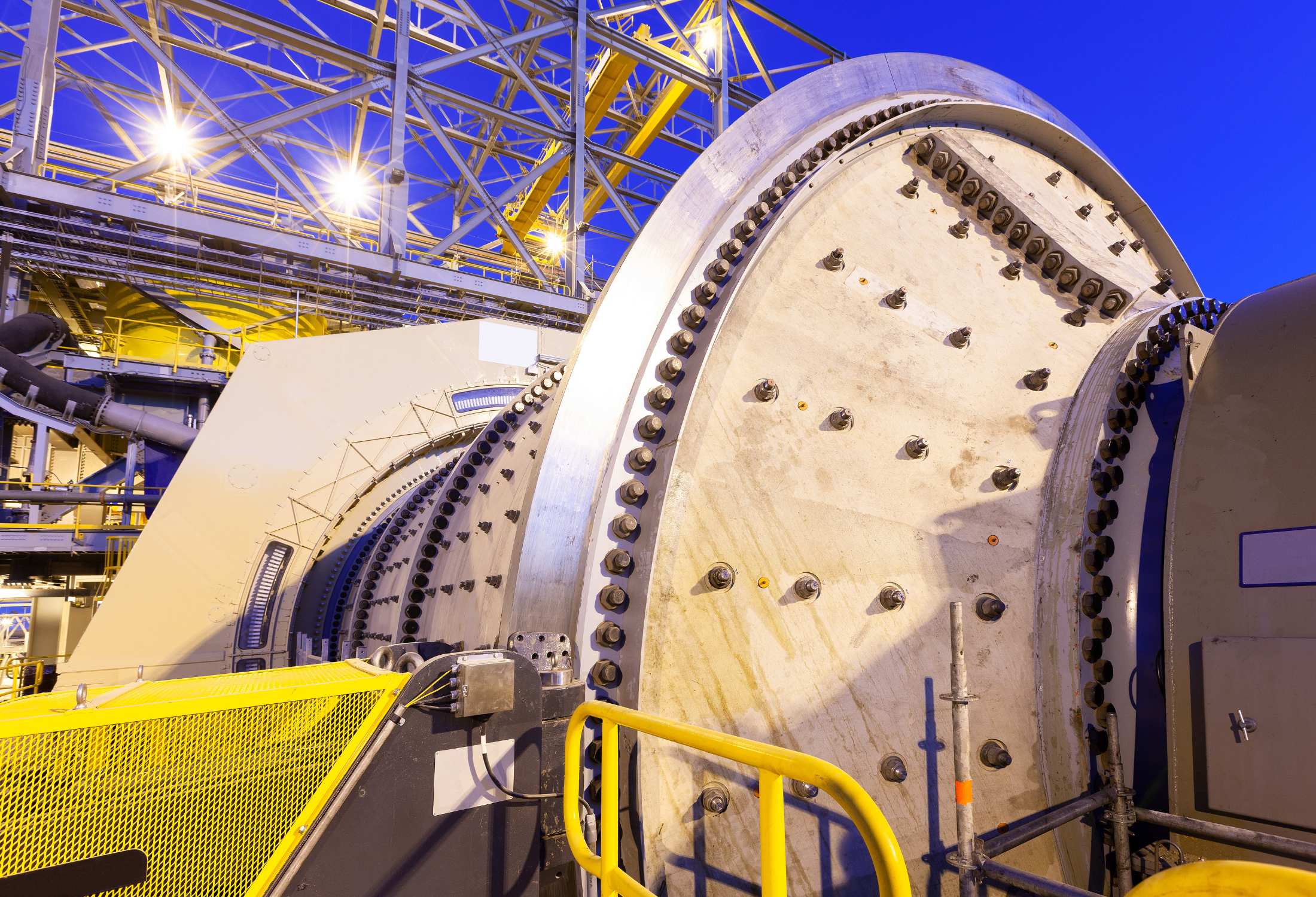

Orway Mineral Consultants (OMC) provided circuit design reviews during the original project inception and design as well as follow-up up circuit surveys and operational reviews. Although these evaluations are exceptionally useful from a value-add perspective, they evaluate specific periods only and are not frequent enough to cater for the dynamic changing operation of the circuit. In most cases, the lack of continual evaluation and implementation of change result in lost revenue, ie opportunity cost losses due to optimisations that could have been implemented sooner.

A period of declining throughput prompted site to pursue various optimisation projects, consisting of Mine to Mill optimisation, advanced instrumentation (MillSlicer), advanced process control (MillStar) and ongoing, real time consulting services (MillROC). MillROC (Milling Remote Optimisation Consulting) is provided by OrwayIQ and consists of frequent and real time feedback to the operations based on live data. Orway IQ is a JV company, harnessing the modelling and consulting expertise of OMC and the control and cloud-based platform of ProcessIQ, to deliver real time consultation and coaching.

.png)

The initial installation and set-up of MillSlicer, MillStar and MillROC was completed by April 2019. The rapid and frequent feedback enabled significant optimisation through the ongoing MillROC service during a period where changes to the feed blend resulted in challenging operating conditions.