.png?ch=192&w=345)

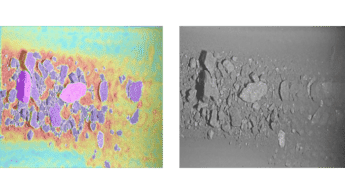

Cyanide Consumption Reduction at an Australian Gold Mine

Cyanide Consumption and Management in a Leaching Circuit at an Australian Gold mine.

Read MoreBy innovating collectively – with our peers and partners – we create new products and services that deliver efficiencies for our customers and the industries in which we operate, toward a better future for all.

For decades, the Molycop name has been synonymous with quality grinding media. Now Molycop is recognised throughout the mining sector for its innovative mineral processing solutions that help customers create and sustain a competitive advantage, while also promoting efficient and sustainable development.

Molycop believes that this is best achieved by innovating new and better technologies and changing our current ways of operating. Sustainability is always front of mind in our approach to innovation.

Our innovation philosophy is informed by the need to provide solutions and products that drive energy efficiency, use recycled materials, improve throughput, reduce waste, and increase recoveries. It also underpins our efforts to reduce our own carbon footprint when we manufacture products, thereby helping the entire industry value chain.

Working hand-in-hand with our peers and partners, we have an innovation strategy in place that focuses on solving the fiscal and social challenges our customers face.

Remaining competitive in today’s minerals market environment means applying innovative products and processes to tackle some of the industry’s entrenched challenges. With our innovation strategy guiding us, our plan is to continue collaborating with our partners to achieve that goal.

.png?ch=192&w=345)

Cyanide Consumption and Management in a Leaching Circuit at an Australian Gold mine.

Read More

Marked Ball Wear Tests (MBWT) are recognized and accepted as a media performance method assessment. But are they well suited to New Product Development (NPD) projects? This research paper takes a deep dive by examining a specific NPD project.

Read More

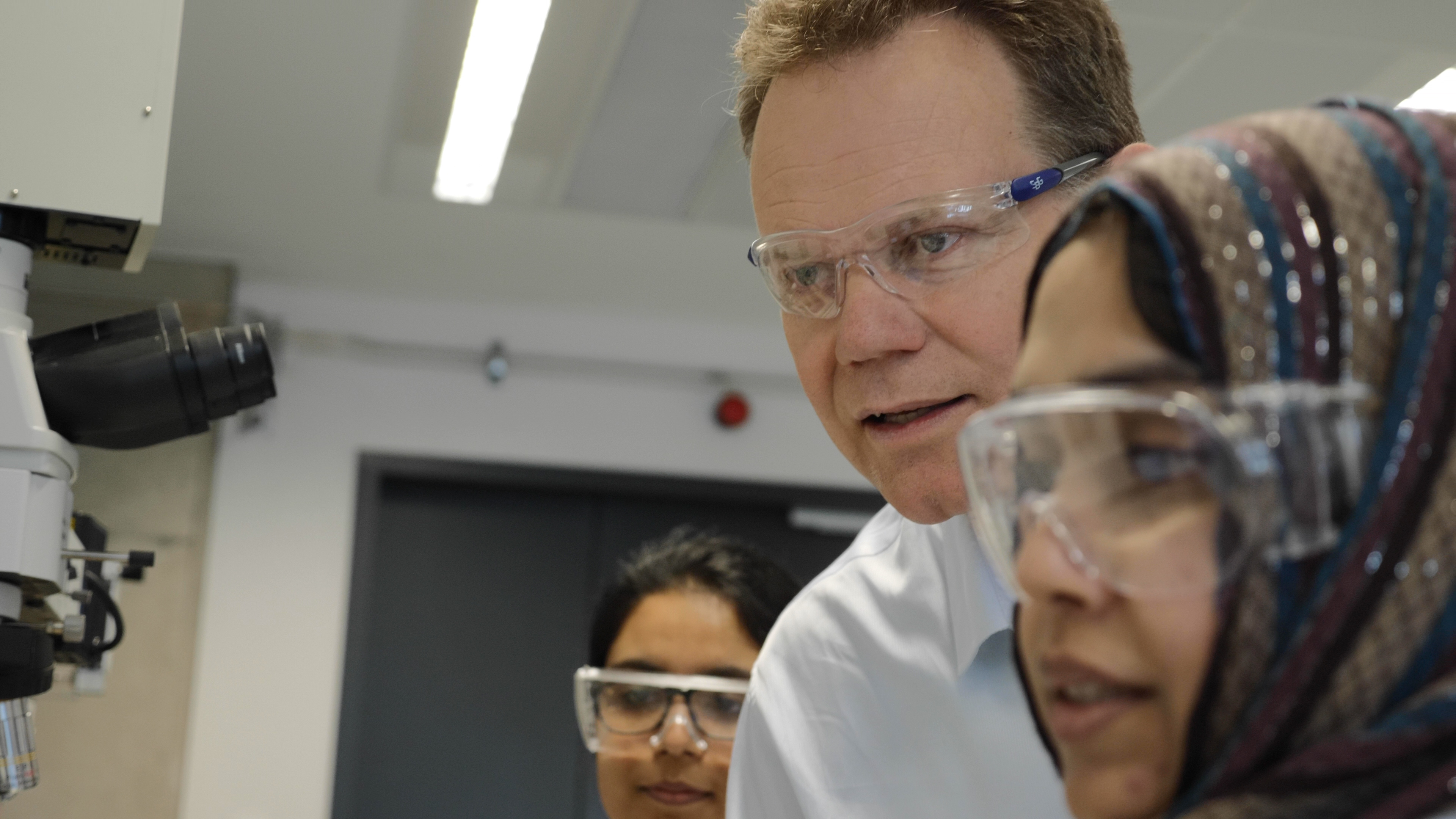

Innovation and product development lie at the heart of a sustainable future for the mining sector, says Paul Shelley, Global Vice President of Innovation, Molycop.

Read More

Molycop has received ARC funding to pursue resource recovery initiatives such as recycling and reuse of coffee grounds and coffee pods.

Read More

Advanced control systems deliver improved outcomes for mineral processing operations.

Read More

OreVia is a suite of advanced AI-based technologies for process characterisation that provide measurements in real time to stabilise and optimise mineral processing operations.

Read More

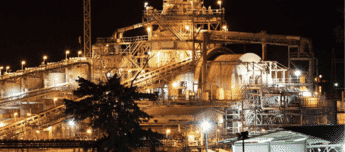

Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services to deliver sustainable increased throughput of 27% in 8 months.

Read More

A gold mine test of marked SAG balls showed that Molycop’s 125mm NG SAG ball exhibited less wear than a competitor’s equivalent SAG ball.

Read MoreWe use cookies, including third party cookies, for operational purposes, statistical analyses, to personalize your experience, provide you with targeted content tailored to your interests and to analyze the performance of our advertising campaigns.

To find out more about the types of cookies, as well as who sends them on our website, please visit our dedicated guide to managing cookies.