A series of simulations were carried out at Brazil’s Sossego Mine that analysed the optimal trajectory of SAG Mill internal load.

- The ideal liner condition combined with the standard maximum rotation speed offers an optimal trajectory for the grinding media inside the mill.

- Optimising SAG mill rotation speed proved to be an effective strategy for enhancing milling efficiency and increasing plant production.

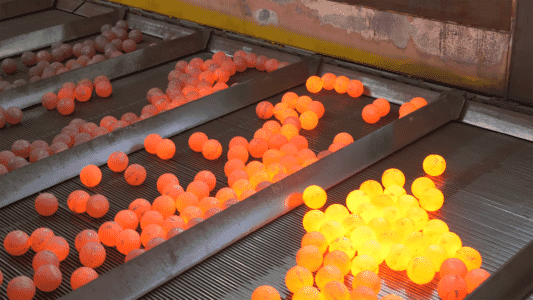

- A controlled increase in the SAG mill’s rotation speed up to 80% showed an optimised trajectory of the grinding media. This led to a significant increase in impact energy, providing a 9.8% improvement in milling energy efficiency compared to a previous scenario.

Overview

A study was carried out at the Sossego processing plant, located in Canaã dos Carajás-PA, Brazil, focused on optimising grinding efficiency in a SAG mill. The SAG mill plays a crucial role in the comminution stage of the studied plant.The study addresses a deviation in the mill cylinder lining change strategy, which reduced the width between plates and impacted grinding efficiency. One of the main variables studied was the rotation speed of the mill, which showed promise in optimising fragmentation during simulations carried out in Molycop Tools. This study contributed to increasing the plant’s productivity and reducing specific energy consumption after implementing the results obtained by the simulations carried out.

The gain came from the application of the study of the optimal point of the grinding load trajectory to compensate for the low load lifting efficiency, caused by the anticipation of changing the lining of the SAG mill.

Molycop Tools simulations

Molycop Tools simulations

Simulations were conducted using Molycop Tools (Version 3.0) for the following three distinct scenarios:

- Scenario 1: Ideal liner condition with standard maximum rotation speed.

- Scenario 2: Current liner condition with standard maximum rotation speed.

- Scenario 3: Current liner condition with increased rotation speed beyond the standard maximum.