Dr Paul Shelley, VP Innovation at Molycop, has co-authored a paper for journal Minerals Engineering that shows how energy wastage in semi-autogenous grinding mills can be reduced.

- Material processed within grinding mills demonstrate a wide range of behaviours.

- Zones of distinct behaviour are categorised based on physical properties.

- Physics-based behavioural zones allow to adjust and optimise industrial processes.

Semi-autogenous grinding mills are used widely to reduce the size of mined ores and extract minerals of interest. However, these mills are extremely energy consuming. To reduce the energy wasted by mostly moving and shearing instead of grinding the material, a good understanding of the behaviour of the charge in the mill is crucial.

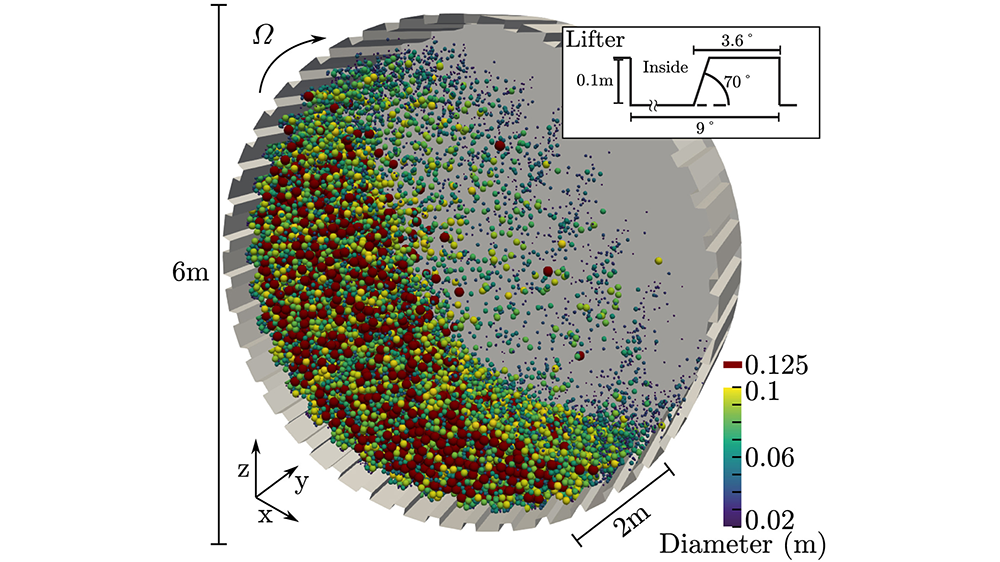

View of a simulated mill with ore particles coloured by their diameter from blue to yellow. Red particles represent steel grinding balls.

View of a simulated mill with ore particles coloured by their diameter from blue to yellow. Red particles represent steel grinding balls.The co-authors first establish different smooth fields of internal variables such as density, strain rates and pressure for a rotary mill simulated using discrete element modelling. These fields are interrelated so a clustering method is then used to identify well-defined zones of distinct behaviour within the mill.

This approach allows the co-authors to analyse and summarise the behaviour of complex flows as a set of localised zones with well-identified physical properties. The dependence of those zones on the operating parameters of the mill provides a direct interpretation of the effects of adjusting the available operating conditions in the field.

The method can be readily generalised to other geometries and particle technologies. This means it can provide a convenient approach for both comprehensive and manageable understanding of material behaviour in a wide range of applications.