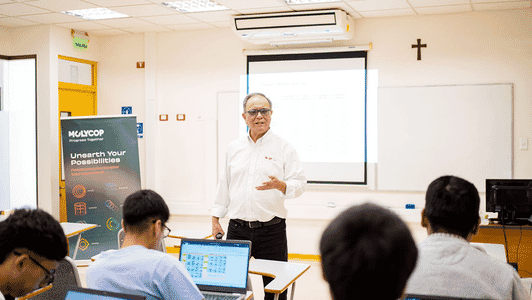

Molycop experts in Chile hosted a course for mining personnel on best practices and emerging trends in milling, and how to elevate productivity and competitiveness.

Key Facts

- Personnel from a leading mining operation in Chile attended Molycop’s ‘Optimisation and Control of Internal Load in SAG Milling’ course.

- Two sessions were held, with a focus on MillSlicer VIP, an advanced mill sensor solution designed to capture valuable insights into the milling process.

- Molycop is passionate about building genuine partnerships with its customers.

The course covered best practices and emerging trends in milling and provided an interactive platform to discuss shared challenges and success stories.

The course covered best practices and emerging trends in milling and provided an interactive platform to discuss shared challenges and success stories.

Exploring advanced technologies for process optimisation

Exploring advanced technologies for process optimisation

A key highlight of the sessions was Molycop's cutting-edge MillSlicer VIP technology, an advanced mill sensor solution designed to capture valuable insights into the milling process. MillSlicer VIP allows operators to gather and analyse real-time data, pinpointing areas for process refinement and driving actionable improvements. By implementing technologies like MillSlicer VIP, Molycop customers can make informed decisions that maximise throughput, minimise energy consumption and optimise operational costs – all critical components in today’s mining landscape.

Empowering knowledge and fostering innovation

Empowering knowledge and fostering innovation

The sessions were led by experienced team members Fernanda Barrera, Applications Deputy Manager, and Andrés Aránguiz, Applications Engineer.  Both are dedicated to supporting customers' journeys toward operational efficiency and sharing their expertise to equip attendees with practical techniques and best practices in SAG milling. Molycop’s advanced tools, application knowledge and ongoing technical support enable its customers to confidently optimise their process, elevating productivity and competitiveness.

Both are dedicated to supporting customers' journeys toward operational efficiency and sharing their expertise to equip attendees with practical techniques and best practices in SAG milling. Molycop’s advanced tools, application knowledge and ongoing technical support enable its customers to confidently optimise their process, elevating productivity and competitiveness.

Thanks to Molycop’s partners

Thanks to Molycop’s partners