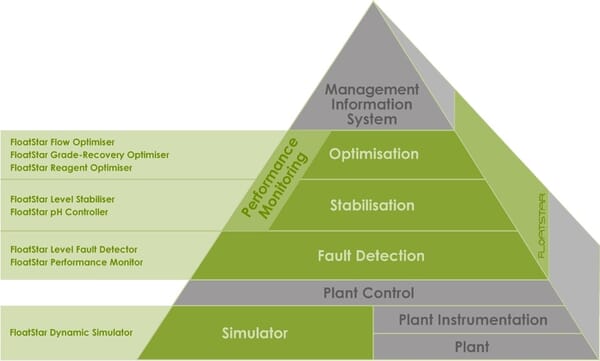

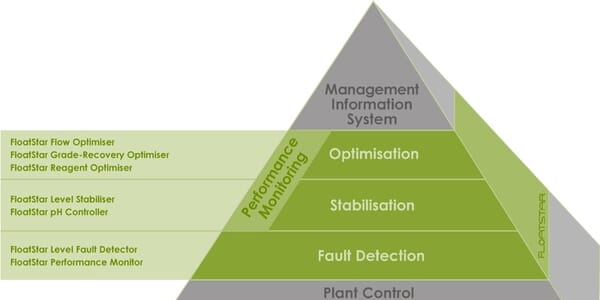

Flotation is a complex process that is affected by a multitude of factors. These factors may be inherent in the circuit design, or in how the flotation plant is operated. The FloatStar suite of control modules, from Mintek, utilises advanced process control to overcome design-related limitations and maximise circuit performance during operation.

As far as possible, the FloatStar control modules are designed to be implemented with little or no additional instrumentation. This modular approach ensures the design of a customised solution, specific to the objectives of each plant. Furthermore, this approach allows for phased implementations that are useful both in assessing the benefit of the system and in allowing plant personnel to be introduced gradually to any changes in operation.

Benefits of FloatStar

FloatStar provides a number of advantages:

- Maximised circuit performance

- Increased recovery

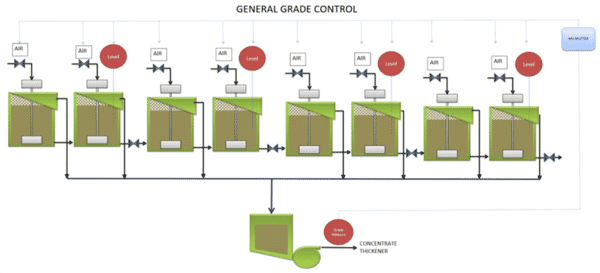

- Accurate grade control

- Optimised reagent usage.

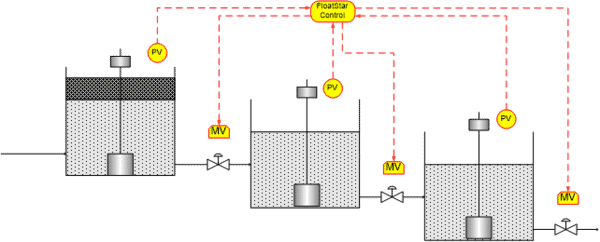

The FloatStar Level Stabiliser

The FloatStar Level Stabiliser has been implemented on flotation circuits around the world. It has repeatedly been proven efficient in rejection of disturbances and in rapid tracking of setpoints.

The main difficulty in controlling flotation levels is that they form part of a highly interconnected system. The control actions of one bank will therefore influence other banks and, unless handled correctly, disturbances will propagate through the circuit. This means that good level stabilisation control cannot be achieved by using controllers that only act locally.

Additional stabilisation

The control of pH is required in a vast number of areas in the mining industry. A key area is in flotation reagent control systems. There are a number of difficulties in controlling pH:

- Non-linearity of the pH curve

- Silting up of the base (typically CaOH) feed-valve

- Compensating for changing feed conditions.

The FloatStar pH controller is designed to handle all of these control difficulties.

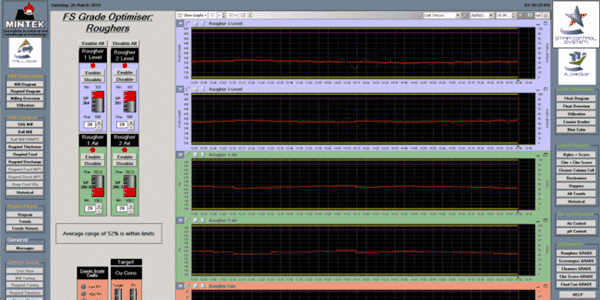

Optimisation

With the FloatStar Level Stabiliser providing circuit stability and rapid setpoint tracking, it becomes possible to consider flotation optimisation.

The FloatStar Flow Optimiser controls circulating loads and mass pull in the flotation circuit. It is well known that circuit performance (grade and recovery) is strongly affected by these parameters. By stabilising circulating load and mass pull, it is possible to ensure consistent circuit performance.

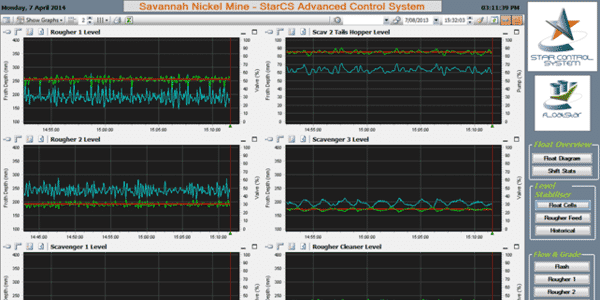

Process monitoring

Controllers must not only perform well in the conditions under which they were installed and tuned, but must also be robust through fluctuating plant conditions.

The FloatStar Performance Monitor keeps track of controller performance at all times and produces useful diagnostic information to analyse when and why controllers are not performing at their peak. Both plant personnel and control engineers will find this information useful in ensuring that their controllers are always performing well.

.png?h=300)