Accelerate product development to address mining’s biggest challenges

Innovation and product development lie at the heart of a sustainable future for the mining sector, says Paul Shelley, Global Vice President of Innovation, Molycop.

Read More

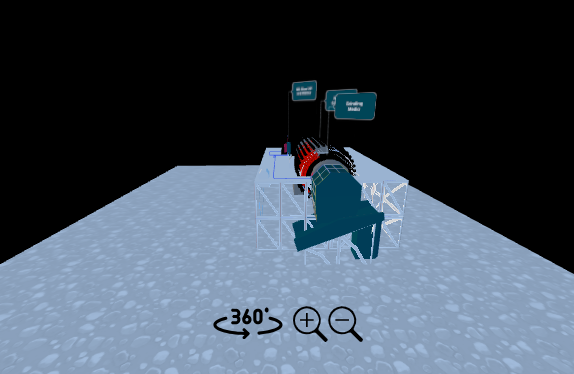

The MillStar Advanced Control System offers a comprehensive suite of control strategies that can be applied to provide an innovative control solution for almost any milling circuit configuration.

Make An Enquiry

Due to the complex nature of milling circuits, conventional control often does not address many of the common problems experienced. Among the problems faced are:

The MillStar Advanced Control System, from Mintek, boasts a typical payback period of just a few months. MillStar allows you to:

Milling is a highly interactive dynamic system that is constantly changing. With MillStar Model Based Control it is possible to predict future behaviour and stabilise your circuit.

MillStar provides a number of advantages:

The smooth operation of a milling circuit is difficult to achieve due to the varying nature of the feed material and the unfavourable dynamics between feeders and the weightometer. These dynamics degrade the performance of the PID controller, making feed optimisation more challenging.

MillStar’s Mill Feed Controller will compensate for the feed dynamic by modelling feeder responses, adapting for any model errors, and adjusting the feeder speeds in a desired ratio.

For the most productive milling operation it is often best to operate close to the maximum mill power draw. The power-load relationship is highly non-linear and shifts around as the ore and steel load/liner changes. Traditional control and modelling techniques can therefore not be used. Mintek has developed a Power Optimiser that:

The MillStar Sump/Product Stabilisation focuses on:

Mintek has developed a Model Predictive Controller (MPC) specifically for controlling milling circuits, which offers the following advantages:

Discover the benefits that MillStar offers by efficiently stabilising and optimising your milling circuit.

Take your operations to the next level by exploring these additional products and services.