With the opening of its SAG ball production line and the acquisition of a cast high chrome plant in Indonesia, Molycop is perfectly positioned to meet South-east Asia’s growing demand for high-quality grinding media.

Key Facts

- Molycop has doubled production at its Cilegon plant with a new SAG ball line and added a cast high chrome plant in Cikande, strengthening its South-east Asia presence.

- The expanded production facilities feature cutting-edge heat treatment and exacting quality control processes, providing customers with high-performance grinding media and greater product flexibility.

- Molycop’s in-country manufacturing boosts local employment and supports sustainability while providing faster delivery and improved customer service.

With these advancements, Molycop enhances its ability to provide high-quality grinding media solutions for its customers and strengthens its position as a leader in grinding media manufacturing in Indonesia and in the wider region.

Molycop’s strategic expansion in Indonesia

Molycop’s strategic expansion in Indonesia

The Cilegon plant has been a key part of Molycop’s Indonesia operations for over 25 years. Initially set up to serve the local market, it has now been upgraded to meet the rising demands of the broader South-east Asian mining sector. The new SAG ball production line at Cilegon doubles the plant’s production capacity from 50,000 tonnes to 120,000 tonnes annually. This expansion significantly improves the plant's ability to produce high-quality grinding media for the mineral processing industry.Keith Ritchie, General Manager, Molycop Indonesia, says the opening of the SAG ball line represents a step-change for Molycop’s operations.

The expansion at Cilegon, alongside our cast high chrome production at Cikande, positions Molycop as a comprehensive provider of grinding solutions in South-east Asia. This development significantly enhances our ability to deliver both forged and cast grinding media directly from within the region, reducing lead times and improving supply chain efficiency.

Enhanced product range and customer benefits

Enhanced product range and customer benefits

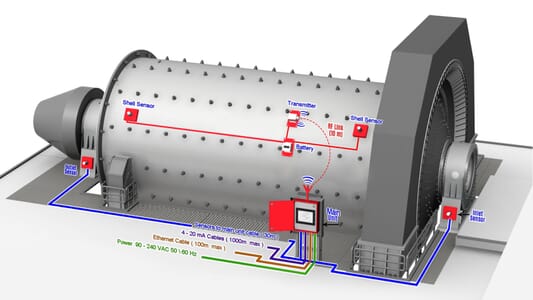

At the heart of Cilegon’s advanced technology is a state-of-the-art heat treatment facility that simultaneously optimises NG SAG abrasion resistance and toughness to maximise performance even in the most demanding mill environments.As well as featuring robust inline processes, the production line offers flexible product switching capabilities to allow for easy scaling up of specific product output as required.

The newly established cast high chrome plant in Cikande, the first to be 100% Molycop-owned, adds another layer to Molycop’s capabilities. The facility produces cast high chrome balls and cylpebs, two types of grinding media known for their high abrasion resistance and durability.

Za’iimatul Husnaa Muharromiyya, Molycop Business Development Manager, says several technological advancements have been applied to ensure product quality:

Za’iimatul Husnaa Muharromiyya, Molycop Business Development Manager, says several technological advancements have been applied to ensure product quality: Both the new SAG ball line and the cast high chrome plant are equipped with multi-layered heat treatment processes and quality control facilities. This ensures that the grinding media we produce are of the highest standard, with consistent hardness, impact resistance and durability. Our customers benefit from reliable products that perform consistently in demanding milling conditions.

Salyo Kahar Dikdoyo, Head of Commercial and Business Development, says the new facilities offer customers even greater product flexibility:

Molycop can now produce a wider range of sizes and compositions, providing customers with more options tailored to specific milling needs. This flexibility allows customers to select the most suitable grinding media for their operational conditions, which can lead to cost savings and improved grinding performance. The increased production capacity at Molycop’s plants means our customers benefit from enhanced supply reliability, shorter lead times, and access to the latest innovations in grinding media.

Sustainability and local engagement

Sustainability and local engagement

Molycop is committed to local manufacturing in Indonesia. Both the Cilegon and Cikande plants are staffed by a predominantly local workforce, contributing to the region’s economic growth and community development. The plants also meet the Indonesian government’s local content requirements, with the Cilegon facility achieving over 50% local content certification.Ritchie says there is strategic value in Molycop’s focus on local manufacturing:

Molycop Indonesia is strongly committed to contributing to the local economy through initiatives that prioritise local hiring, skills training and partnerships with regional suppliers. Our facilities at Cilegon and Cikande actively recruit from the surrounding communities, investing in workforce development through training and upskilling programs.

Molycop also engages with local suppliers wherever possible, integrating local content into production processes and supporting the regional economy. By embedding itself within the local ecosystem, Molycop contributes to both the economic development and empowerment of the communities it serves.

Molycop’s use of local raw materials and its focus on sustainability also help reduce its carbon footprint. The Cikande plant’s use of locally sourced scrap as a raw material supports Molycop’s broader environmental goals, aligning with the company’s commitment to sustainable practices.

A stronger, more resilient future

A stronger, more resilient future

The opening of the new SAG ball production line and acquisition of the cast high chrome plant at Cikande represent a strategic step forward for Molycop in Indonesia. By investing in advanced technologies, expanding production capacity, and focusing on local manufacturing, Molycop has reinforced its reputation as a leader in grinding media solutions.As Keith Ritchie notes:

Our strategic expansion not only allows us to handle higher volumes but also provides us with the flexibility to adapt to varying customer requirements, positioning us as a trusted supplier capable of delivering consistent, high-quality media promptly and efficiently.

Through its continued investments in innovation and customer support, Molycop is poised to remain at the forefront of the grinding media industry in South-east Asia, delivering value to customers and driving operational success across the region.