Dr Paul Shelley, Molycop VP of Innovation, highlights how the energy footprint of the SAG mill is in sharp focus and is driving rethinking in circuit efficiency, equipment and design.

Key Facts

- The mining industry relies on suppliers for its innovation, with the technology embedded in machinery, services and other inputs driving innovation.

- The need for energy efficiency and embracing digital transformation is advancing equipment design and thinking.

- Digital platforms that use advanced statistical techniques, AI and machine-learning are changing the way the sector thinks about milling.

The most significant changes in the mining industry originate from the world’s leading mining companies formally committing themselves to meeting net zero scope 3 carbon emissions by at least 2050. The energy footprint of the semi-autogenous grinding (SAG) mill is in sharp focus and is driving rethinking in circuit efficiency, equipment and design. The resulting initiatives will lead to major changes in SAG milling in the immediate future.

The digital transformation

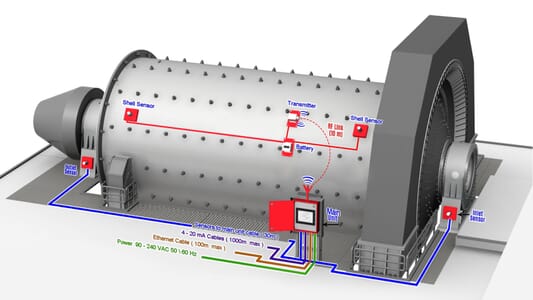

Innovation and Digital Transformation (DT) have emerged as critical players to solve the industry’s challenges.The technology embedded in machinery, services and other inputs allows for innovation to occur in the sector. The current trend is sensor-based monitoring of the process chain including the grinding processes. Value propositions that show how digital platforms use advanced statistical techniques, artificial intelligence and machine-learning algorithms to predict SAG mill operating states in real-time are maturing. These systems have a profound influence on operations now and are changing the way miners think about milling in the near term.

Product development

The drive for energy efficiency and embracing digital transformation is advancing equipment design and thinking. Developing more durable materials for mill liners and grinding media is a significant trend. These types of product development will significantly change the operation of the SAG mill if they do not entirely replace it.

Catalysts of change in the industry ahead

The immediate future of the SAG mill is one of change. Most likely the changes will be:

- Driven by the digital transformation and influence of SAG mill operation and operating paradigms. This seems particularly so in mill monitoring, data analytics, process control and virtual machines.

- Modifications to the existing deployed fleet rather than wholesale replacement.

- Very largely influenced by the validation of emerging equipment like CAHM, HPGR, ore sorting and fragmentation.

- Customisation. Given the variability in ore properties across different mining sites, there is a growing need for SAG mills that can be customised and are flexible in operations.

- Numerous. One can expect incremental, step change and disruption emerging from supplier initiatives.

- Based on the increasing visibility and homogeneity of the feed ore. Variability is the villain.