Optimization of the SAG Ball Line at Molycop's Lima, Peru, site enhances SAG ball production capacity by 20% and adds state-of-the-art innovations that align the site with the evolving needs of the mining sector.

Key facts

- The project completes a strategic move towards enhancing production capabilities at Molycop’s Lima site.

- SAG Ball production capacity has been expanded by an impressive 20%.

- Cutting-edge technology has been implemented to fortify Molycop's position in the market.

On December 19, a momentous occasion unfolded at Molycop's Santa Anita Plant in Lima, Peru, as the Optimization Project for the SAG Ball Line was inaugurated.

The US$5 million initiative ensures that Molycop’s customers and business partners can rely on a steady and superior supply of SAG balls and reflects Molycop's proactive stance in addressing market dynamics. It also underscores Molycop's unwavering commitment to excellence in both product quality and supply chain reliability.

Optimization Project achievements

Among the achievements of the Optimization Project are:

Expanded production capacity

A key objective of the Optimization Project was the expansion of the SAG ball production capacity by an impressive 20%. This forward-looking approach positions Molycop to meet the rising demands of the market while ensuring a reliable and secure supply of this critical input. The investment underscores Molycop's commitment to staying ahead of market requirements and contributing to the sustained growth of the mining industry.

Technological improvements

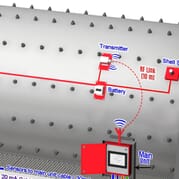

In addition to the capacity expansion, the Optimization Project focused on incorporating state-of-the-art technological innovations developed by the Molycop Group. The aim was to optimize the performance of SAG balls in mining operations, delivering enhanced value to Molycop's customers. By embracing the latest advancements in technology, Molycop has demonstrated its commitment to providing superior products that align with the evolving needs of the mining sector.

Commitment to excellence

The successful inauguration of the Optimization Project underscores Molycop's unwavering commitment to excellence in both product quality and supply chain reliability. This achievement reflects Molycop's proactive stance in addressing market dynamics and ensuring that its customers and business partners can rely on a steady and superior supply of SAG balls.

Outstanding performance by the Molycop team

The project's inauguration marks a significant step forward for Molycop's Santa Anita operation. As the company embraces progress and innovation, it reaffirms its dedication to the continued success of its operations in Peru.

Molycop extends its congratulations to all the individuals involved in the project. Their outstanding performance and unwavering commitment played a pivotal role in the successful execution of the initiative. The collaboration and dedication exhibited by the project team underscore Molycop's belief in the power of teamwork and the collective pursuit of excellence.

The inauguration of the Optimization Project at Molycop's Santa Anita Plant is a testament to the company's commitment to progress, innovation and excellence. This strategic investment positions Molycop for sustained growth, ensuring that it remains at the forefront of the industry.

It also stands as a shining example of the company's proactive approach to meeting and exceeding the expectations of its customers and partners.