Digital mining: Leveraging the gold price

Molycop’s processing optimisation services are improving mining operations globally.

Read More

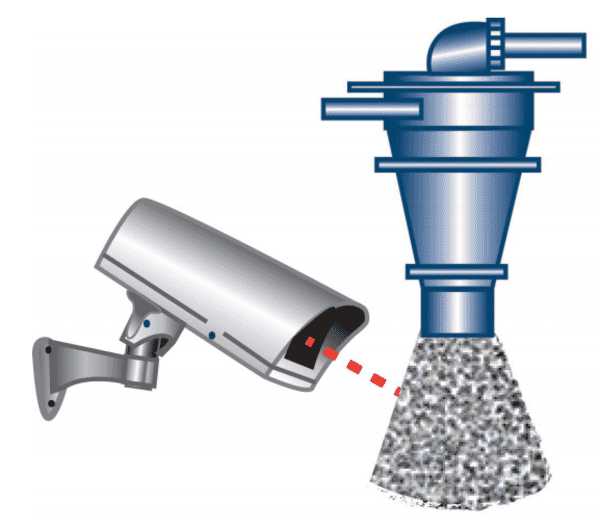

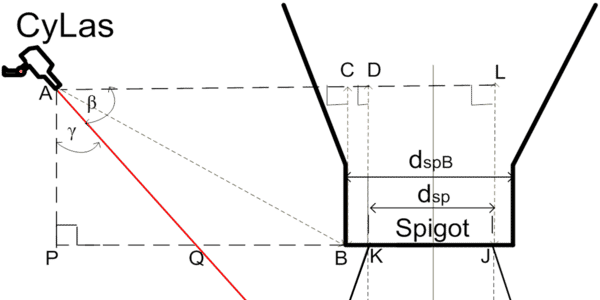

CyLas, a product from Mintek, is an online instrument measuring the hydrocyclone underflow discharge angle.

Make An Enquiry

CyLas, a Mintek product, is an online instrument that measures the hydrocyclone underflow discharge angle.

Plant operators have traditionally used the shape of the hydrocyclone underflow to assess the overall efficiency of the milling circuit – the CyLas provides this information online.

CyLas uses a laser device to measure the distance from a fixed point (where it is mounted) to a point on the hydrocyclone underflow discharge. The distance is then related to the underflow discharge angle with the aid of trigonometric manipulations. Because of its non-contact nature and rugged construction, the CyLas is an inherently low-maintenance instrument.

CyLas monitors the performance of a cyclone by providing a continuous measurement of the discharge angle of the underflow. This allows for optimal cyclone performance by altering feed conditions to operate the cyclone close to roping without choking.

Control of the underflow angle allows for consistent and optimal recirculating load conditions (in terms of flow and density) and ultimately limits the chances of mill overload due to the recirculating flow.

Among its benefits:

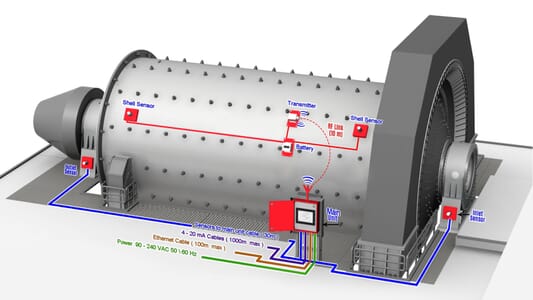

By integrating CyLas with our comprehensive suite of milling solutions, including Rock IQ, MillSlicer VIP, MillROC, and MillStar, we offer an enhanced and synergistic approach to optimising the entire milling circuit. Together, these integrated solutions ensure improved performance and efficiency throughout the milling process.

Take your operations to the next level by exploring these additional products and services.

Molycop’s processing optimisation services are improving mining operations globally.

Read More

Dr Paul Shelley, VP Innovation at Molycop, has co-authored a paper for journal Minerals Engineering that shows how energy wastage in semi-autogenous grinding mills can be reduced.

Read More

Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services to deliver sustainable increased throughput of 27% in 8 months.

Read More

The Ball MillSlicer utilises the latest in digital signal processing techniques available to provide an accurate view of the change in mill fill level (vectors).

Read More

The Ball MillSlicer utilises the latest in digital signal processing techniques available to provide an accurate view of the change in mill fill level (vectors).

Read More

Our milling product range has been designed and manufactured to high performance standards for strength, impact resistance and wear. Offering a range of forged, cast high-chrome or ceramic grinding media, Molycop's product range can deliver the results you need.

Read More

At Molycop, we see innovation as a way to find solutions to some of the mining industry’s greatest challenges. We aim to improve on today so we can deliver better for tomorrow.

Read MoreWe use cookies, including third party cookies, for operational purposes, statistical analyses, to personalize your experience, provide you with targeted content tailored to your interests and to analyze the performance of our advertising campaigns.

To find out more about the types of cookies, as well as who sends them on our website, please visit our dedicated guide to managing cookies.