Marked Ball Wear Tests (MBWT) are recognized and accepted as a media performance method assessment. But are they well suited to New Product Development (NPD) projects? This research paper takes a deep dive by examining a specific NPD project.

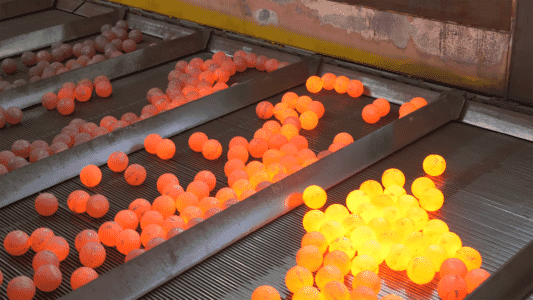

- Grinding media costs in milling processes are significant – often 30–50% of the total milling cost.

- This paper highlights difficulties with Marked Ball Wear Test methodology for New Product Development processes.

- It proposes testing processes for better assessing grinding media products and accelerating grinding media product development.

The most widely recognized media performance assessment method is the Marked Ball Wear Test (MBWT). Although MBWT is a very reliable in-service evaluation method, it is not well suited for New Product Development (NPD) projects because it is doesn’t match key critical success factors of modern NPD processes.

This paper examines a specific NPD project using a result extract from MBWTs undertaken in two mills in South America. Twelve grinding media products were trialled simultaneously in two very different operating environments.

This research paper examines the philosophy and design of the MBWT experiment in a product development process – and provides a snapshot of the results. It highlights difficulties with MBWT methodology for a NPD process and proposes a recent testing process that has the potential to enhance the ability to assess grinding media products and accelerate grinding media product development.