Molycop has developed an advanced intelligent computational framework—Molycop Digital Engine—that can be used to optimize the performance of comminution circuits. Our latest research paper explores how mill operators can use it to maximize productivity and improve operational efficiency.

- Molycop Digital Engine can predict the behaviour and optimise the performance of comminution circuits.

- Digital Engine has been successfully applied to predict the performance of a SAG mill at a mineral-processing plant in Western Australia.

- By leveraging fundamental models and experimental data, Digital Engine empowers users to gain valuable insights and make informed decisions in pursuit of optimization.

This research paper explores how the Digital Engine uses advanced statistical techniques, artificial intelligence (AI) and machine-learning algorithms to achieve its objectives. It can be used to create and deploy digital twins using both long-term and short-term historical data from a SAG mill and other mineral-processing units.

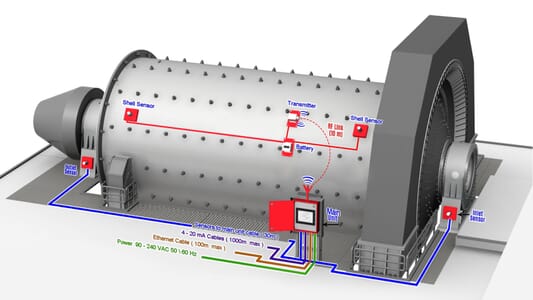

The Digital Engine was employed to predict the performance of a SAG mill at a mineral-processing plant in Western Australia. The Molycop mill monitoring sensor system, including shell and media sensor data, was incorporated with the main operating variables. The shell sensor measures the energy of impacts around the mill circumference, while the media sensor captures impacts within the mill charge.

The Digital Engine uses data from these sensors and other key operating variables to can enhance its predictive capabilities and provide a comprehensive understanding of SAG mill performance.

A valuable tool

The Design Engine’s intelligent computational framework, advanced algorithms, and real-time optimulation capabilities make it a valuable tool for mill operators seeking to enhance performance, maximize productivity and improve operational efficiency.The example of the mineral-processing plant in Western Australia shows there is immense potential for widespread adoption of the Digital Engine in the mining industry. The successful application of the Digital Engine not only demonstrated its effectiveness and value but also reaffirmed its reliability and importance in real-world scenarios.