Outstanding performance recognised at Molycop’s Excellence Awards 2025

Molycop’s Excellence Awards celebrate individuals and teams who promote the company’s values in everything they do.

Read MoreDiscover the latest in mineral processing through Molycop’s news, case studies and webinars. Schedule a meeting with our Technical Services team at upcoming industry events and explore our extensive Knowledge Library to stay ahead in the mining industry.

Molycop’s Excellence Awards celebrate individuals and teams who promote the company’s values in everything they do.

Read More

Industry veteran Alain Lajeunesse has stepped down from his role at Molycop after 33 years, bringing to an end a remarkable career in mining.

Read More

Molycop has joined as a Bronze Sponsor of the 2025 Breast Cancer Trials (BCT) fundraising campaign, underscoring its commitment to supporting life-saving research and making a positive impact in the communities it serves.

Read More

Flotation is a critical but frequently underestimated stage in mineral processing. Molycop’s Advanced Process Control Manager, Kobus Oosthuizen, understands what common mistakes are made and how to avoid them.

Read More

Molycop’s Account Manager for eastern Canada, Chad Long, draws on a rich background in construction, civil engineering and sales to strengthen customer relationships and support mining operations across the region.

Read More

Molycop enables U.S. mineral processing plants to unlock greater performance and efficiency with tailored Advanced Process Control (APC) solutions that combine deep process expertise with operator-focused support.

Read More

Molycop’s partnership with Queen Mary University of London (QMUL) is delivering early breakthroughs in alloy design for grinding media, blending advanced computational modelling with real-world manufacturing to drive performance and sustainability in mining.

Read More

As Molycop expands its footprint across South-east Asia, Senior Applications Engineer Irfan Satria Putra enables customers to optimise grinding performance, reduce costs and drive long-term success with his thorough technical expertise and local insight.

Read More/dalgarange-gold-mine.png?ch=192&w=345)

An Australian gold mine undertook a marked ball wear test in July 2024 that proved the effectiveness of Molycop’s 90mm 15%Cr cast high chrome ball.

Read More

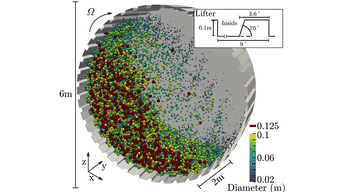

A series of simulations were carried out at Brazil’s Sossego Mine that analysed the optimal trajectory of SAG Mill internal load.

Read More

A gold mine test that conducted over 517 mill operating hours revealed impressive results for Molycop’s forged and high chrome cast grinding media.

Read More

A gold mine test of marked SAG balls showed that Molycop’s 125mm NG SAG ball exhibited less wear than a competitor’s equivalent SAG ball.

Read More

Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including mine-to-mill optimisation, advanced instrumentation, and real-time consulting services to deliver sustainable increased throughput of 27% in 8 months.

Read More.png?ch=192&w=345)

Cyanide Consumption and Management in a Leaching Circuit at an Australian Gold mine.

Read More.png?ch=192&w=345)

The objective of a MillROC improvement project at a leading Australian nickel mine was to implement a new control philosophy around the grinding circuit, which allowed for stabilisation of key operating variables. The project led to significant improvement in circuit efficiency, reduction in energy requirements and increases in throughput.

Read More.png?ch=192&w=345)

Morobe Consolidated Goldfields Limited, a subsidiary of Harmony Gold, has been operating the Hidden Valley Gold and Silver mine in Papua New Guinea. In 2021/2022, the company installed six Mintek online carbon concentration meters (C2 Meters) in their Carbon-In-Leach (CIL) circuit to evaluate the benefits of real-time carbon measurement for automated carbon management.

Read More

Molycop is committed to the highest ethical and legal standards in the way we conduct our business. Molycop expects and requires that all parties who are doing business with Molycop act with integrity and acknowledge and agree to abide by the values, policies and principles in this Molycop Suppliers Code of Conduct.

Read More

This Forced Labour and Child Labour Report (Modern Slavery Report) describes the reasonable steps taken by Moly-Cop to mitigate forced labour and child labour in our organisation’s operations and supply chains during the 2023 fiscal year.

Read More

Molycop is committed to high standards of conduct in all of its business activities, and to promoting and supporting a culture of honest and ethical behaviour, compliance and good corporate governance. Molycop encourages any person who becomes aware of any Reportable Conduct to raise those concerns in accordance with this Policy.

Read More

Cyanide Consumption and Management in a Leaching Circuit at an Australian Gold Mine.

Read More

A gold mine test that conducted over 517 mill operating hours revealed impressive results for Molycop’s forged and high chrome cast grinding media.

Read More

Marked Ball Wear Tests (MBWT) are recognized and accepted as a media performance method assessment. But are they well suited to New Product Development (NPD) projects? This research paper takes a deep dive by examining a specific NPD project.

Read More

The minerals industry appears slow to adopt the use of image processing applications and more comprehensive flotation models in industrial APC applications. This research paper explains why and offers an example of the challenges faced.

Read More

Six C2 carbon concentration meters installed in PNG’s Hidden Valley Gold and Silver Mine have improved carbon management in the mine’s CIL circuit and significantly optimised metal recovery.

Read More

Marked Ball Wear Tests (MBWT) are recognized and accepted as a media performance method assessment. But are they well suited to New Product Development (NPD) projects? This research paper takes a deep dive by examining a specific NPD project.

Read More

Dr Paul Shelley, VP Innovation at Molycop, has co-authored a paper for journal Minerals Engineering that shows how energy wastage in semi-autogenous grinding mills can be reduced.

Read More

This paper demonstrates how convolutional neural networks (CNNs) have the potential to classify abnormal froth conditions and maintain the efficiency of the flotation process.

Read More

Molycop has developed an advanced intelligent computational framework—Molycop Digital Engine—that can be used to optimize the performance of comminution circuits. Our latest research paper explores how mill operators can use it to maximize productivity and improve operational efficiency.

Read More

Six C2 carbon concentration meters installed in PNG’s Hidden Valley Gold and Silver Mine have improved carbon management in the mine’s CIL circuit and significantly optimised metal recovery.

Read More

The minerals industry appears slow to adopt the use of image processing applications and more comprehensive flotation models in industrial APC applications. This research paper explains why and offers an example of the challenges faced.

Read MoreWe use cookies, including third party cookies, for operational purposes, statistical analyses, to personalize your experience, provide you with targeted content tailored to your interests and to analyze the performance of our advertising campaigns.

To find out more about the types of cookies, as well as who sends them on our website, please visit our dedicated guide to managing cookies.